Does the wizard choose the wand? Or does the wand choose the wizard?

Does the wizard choose the wand? Or does the wand choose the wizard?

If there is one person who knows the answer to this intriguing question, it is Lane O’Neil, the master wandmaker behind Gray Magic Woodworking. Lane brought his wands, tools, and expertise to our library’s Harry Potter Wand Works event, and we couldn’t have been more delighted.

Even though Lane has been woodworking for 25 years, he didn’t take up the wand making lathe until fairly recently. Four years ago, during a hike, he picked up an oak branch. He carved the branch into his first wand – a gift for his young daughter. 291 hand-crafted wands later, Lane is still busy carving and shipping his unique pieces around the world.

Fantastically, Lane donated 3 of his wands to our Accio Wand blog contest! Readers of all ages were invited to submit an original Harry Potter spell, be it silly or serious. The winning entries are posted here.

Fantastically, Lane donated 3 of his wands to our Accio Wand blog contest! Readers of all ages were invited to submit an original Harry Potter spell, be it silly or serious. The winning entries are posted here.

How did you first get interested in wandmaking?

I got interested in wandmaking slowly over time. I enjoyed the Harry Potter movies, and being an artist, I was instantly drawn to the concept of each witch or wizard having a unique wand. They were made from different woods, had different cores, and were made by different wandmakers. The idea that the wand was linked to the person was wonderful. Sometimes the style fit the personality like Hermione, Sirius, or Narcissus. And sometimes it didn’t, like Ginny, Harry, or Mad-Eye. Sometimes the wand only reflected the holders shallow exterior, like Delores Umbridge, or what beauty was hidden beneath the surface, like Luna.

I had vision upon vision in my head of new pieces to create. And I got to work. I wanted each piece to be unique. I love the idea of the wand being paired to one person. It’s less of a part time job now, more of a labor of love.

What sorts of woods do you use?

What sorts of woods do you use?

When I first started, I used what was readily available, Oak, Poplar, Ash, Maple. But as I discovered, there are hundreds of species of trees. I now use Paduak, Gaboon Ebony, Birch, Purpleheart, Cherry, Bubinga, Cocobolo, Koa, Osage Orange, Mahogany, Lacewood, you name it. The more exotic and far traveled it is the better. I love the different textures, grains, colors, and figures.

Where do you acquire the wood for your wands?

Where do you acquire the wood for your wands?

I get wood wherever I can. Found pieces, traded pieces among my woodworking group, but primarily I use exotic hardwood suppliers. I got requests to craft from Holly, Elder, and Larch. And since I just couldn’t run down to Home Depot and pick up some Bolivian Rosewood, I needed to branch out and discover new suppliers.

My favorite place is called Hearn, they are located in Oxford, PA. It’s like a candy store for people who craft wood. They have everything from domestic scraps to 16′ slabs of exotic wood shipped from the hearts of far away continents.

My favorite place is called Hearn, they are located in Oxford, PA. It’s like a candy store for people who craft wood. They have everything from domestic scraps to 16′ slabs of exotic wood shipped from the hearts of far away continents.

Describe the process of carving a wand from start to finish.

I start with a dried, seasoned “blank.” It’s usually about 1″X1″x16″. I drill a small shallow hole into each end to secure it in the lathe. I remove the Morris Taper spur from the lathe, tap it onto the wood blank, insert the spur/wood onto the lathe, and lock in the tail stock. I make sure I have my safety goggles and breathing respirator on, and my sleeves rolled up.

I position the guide, turn on the lathe, and use a “roughing gouge” to take the edges off until I have a smooth, long cylinder. I can then draw lines, if needed, for length or detail locations. Then I use various skews and chisels to shape the wand.

When it’s just about fully shaped, I use sandpaper to smooth it – working to smaller grits until I’m happy with the texture. I can also stain or paint the wand while it’s spinning. I usually use a carnauba wax/ tung oil blend to finish fully.

When it’s just about fully shaped, I use sandpaper to smooth it – working to smaller grits until I’m happy with the texture. I can also stain or paint the wand while it’s spinning. I usually use a carnauba wax/ tung oil blend to finish fully.

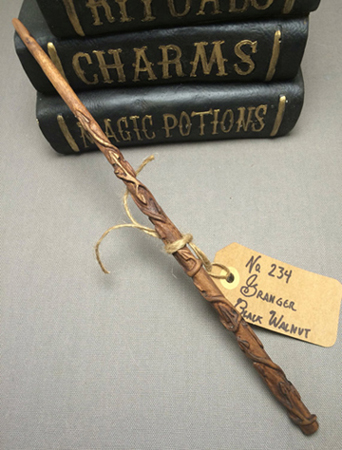

When I’m just about done, I “part” the wand from the lathe by cutting the material away by the tip or pommel until the wand falls off. I move the piece to the work bench, saw the remaining scrap block off, sand the two rough ends, and finish with carving, wood burning, or other decorations. I tag it, give it a name, and a number.

When I’m just about done, I “part” the wand from the lathe by cutting the material away by the tip or pommel until the wand falls off. I move the piece to the work bench, saw the remaining scrap block off, sand the two rough ends, and finish with carving, wood burning, or other decorations. I tag it, give it a name, and a number.

How long does it take to make a wand?

How long does it take to make a wand?

The time it takes to make a wand depends on the intricacy. The first wand I ever turned took an hour and half…and it was kind of rough. I spent about 80% of the time carving and shaping, and 20% sanding and finishing. Now it’s more like 40% of the time carving and shaping, and 60% finishing. I under-valued the worth of the finish when I got started, but my skill improved.

I made 22 wands for my daughter’s class for Valentine’s – real simple and basic. Those took 4 minutes each. I also made one covered in carved vines that took 8 hours. But the average time would be 45-60 minutes.

What locations have your wands shipped to?

What locations have your wands shipped to?

I’ve shipped as far North as Fairbanks Alaska, as Far East as Taipei Taiwan, as far South as Singapore, and as far West as Anchorage, Alaska. All over Europe and Saudi Arabia too.

What’s the most unusual or significant wand you’ve ever made?

What’s the most unusual or significant wand you’ve ever made?

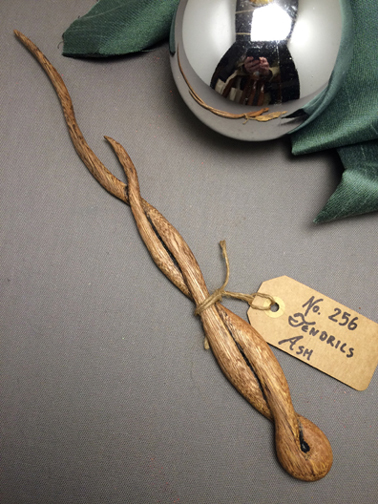

The most unusual wand I ever made was a hand carved series of twisted “vines.” It appears to be woven, but is actually sculpted out of a block of wood.

The most significant wand I’ve ever made is a tie. I made a Beech wand that was chosen by a young girl from the Make-A-Wish Foundation. There wasn’t anything too special about it other than the leather wrapped handle, but she chose it.

The most significant wand I’ve ever made is a tie. I made a Beech wand that was chosen by a young girl from the Make-A-Wish Foundation. There wasn’t anything too special about it other than the leather wrapped handle, but she chose it.

The other one was purchased by a mother in London, England. She bought a Japanese Maple for her son Harry for his 10th birthday…that was pretty cool. His mother sent me a photo.

The other one was purchased by a mother in London, England. She bought a Japanese Maple for her son Harry for his 10th birthday…that was pretty cool. His mother sent me a photo.

Photos courtesy of Gray Magic Woodworking.